Reverse Osmosis Systems

Scaling/Fouling is considered to be one of the most important part in the design and operation of the membrane systems.

Scaling can be recognized as accumulation of constituents and particles in the feed stream of the membrane which is caused through several physical, chemical and biological mechanisms that leads to accumulation of solid material onto the membrane surface. One of the major concerns for membrane scaling is the impurities in the feed water which increase the pore size of the membranes as the solid matter's size is larger than the membranes pore size or the impurities get stuck in the pores of the membranes thereby blocking or narrowing the membrane pore.

Scaling should not only be prevented or reduced but if possible should be eliminated from the membrane systems which can be done through several physical and chemical means.

Learn More

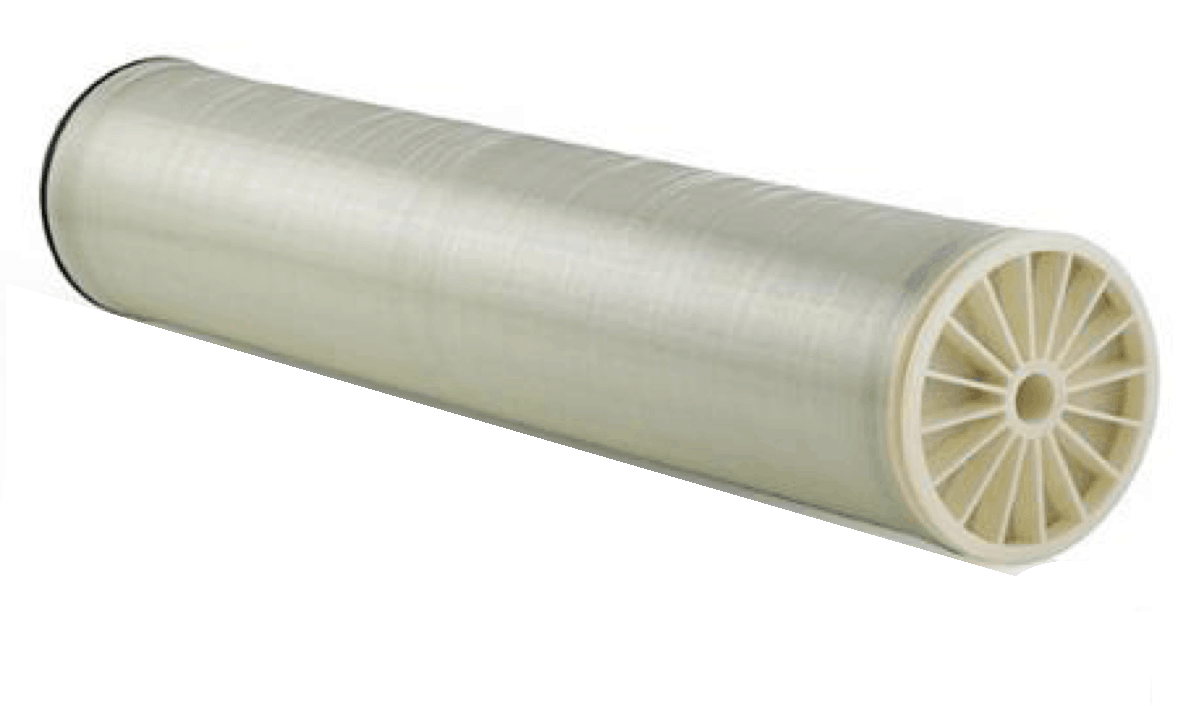

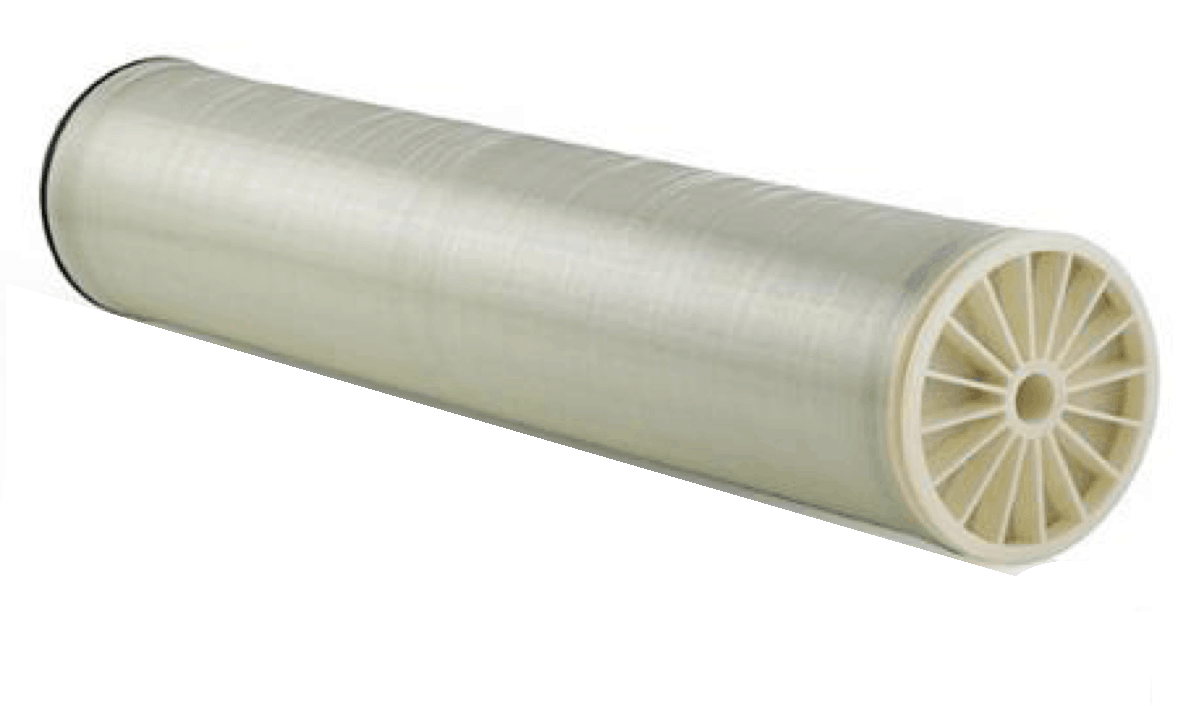

Membrane is the most crucial part of the RO systems and thereby requiring acute diligence. We at Aquapower will confirm to the overall processing of your membrane through uninterrupted and high tech services to help you reach optimal efficiency.

Scaling/Fouling is considered to be one of the most important part in the design and operation of the membrane systems. Scaling can be recognized as accumulation of constituents and particles in the feed stream of the membrane which is caused through several physical, chemical and biological mechanisms that leads to accumulation of solid material onto the membrane surface.

Scale or fouling if not attended on time can cause severe problems such as high operating costs, low membrane life, less recovery, lower efficiency and many more. AquaPower offers complete range of membrane treatment chemicals. AquaPower offers customer friendly and tailor made chemicals for chemical cleaning of membranes. For Organic fouling and inorganic fouling we offer you AquaPower's best AQUACLEAN 14, AQUACLEAN 17 and AQUACLEAN 23.

How AquaPower competes with other players in this industry?

AquaPower offers a Fail-proof and Tailor-made technical chemical cleaning treatment program. Your regular chemical cleaning might be giving good results but AquaPower's Chemical treatment program will introduce you to your membranes best performance and Increase its operating Efficiency irrespective of the feed water source. Alkaline and Acidic cleaning chemicals ensures reliable performance with improved recovery, protecting membrane damages and healthy reverse osmosis plant operations.

Benefits of AquaPower's chemical cleaning treatment program are:

- User friendly.

- Less time consuming and innovative treatment program.

- Compatible with all RO systems and membranes.

- Scale Inhibition and corrosion control.

- Increases the RO membrane efficiency.

- Ensures better plant and membrane operation & increases equipment life span.

- Highly Economical

- Non Oxidizing biocides for removal micro-biological fouling.

Processes run at their optimal efficiency and minimal waste give higher returns. We at Aquapower will ensure smooth functioning and minimal exhaustion of resources through our RO Antisclants.

The types of Reverse Osmosis Systems service provided by AquaPower are:

- Sea Water RO

- Brackish Water RO

- Drinking water RO

- Ultra-Filtration systems

- Nano-Filtration systems

- All types of RO membranes

- Cartridge Filters

- Antiscalants/Antifoulants

- RO Membrane Cleaning chemicals

- RO plant O&M

- Resins

- Activated Carbon Filters

- Pressure Sand Filters

ANTISCALANTAQUAPRO 20

ADVANTAGES:

- AquaPower's AQUAPRO 20 is a highly effective antiscalant with any pH range. It gives excellent results and is very promising for any type of scales and can handle absolutely any change in inlet water parameters.

- AquaPower's AQUAPRO 20 can control impurities in feed water with high LSI up to +2.75.

- All scale forming minerals like oxides, calcium, magnesium, aluminium, sulfates, silica and many more can easily be treated and desired water quality is achived.

- AQUAPRO 20 gives promising results with all types of RO membranes.

- Provides noticeable change in the permeate water flow.

- Highly Economical

KEY FEATURES & BENEFITS:

- Scale Inhibition and corrosion control.

- Ensures the membrane increased efficiency.

- User friendly

- Provides excellent results with all RO systems and membranes.

- Ensures better plant and membrane operation &increase equipment life span.

- Highly Economical.

PRODUCT PROPERTIES:

- Form: Liquid

- Appearance:Colourless to Pale Yellow

- Odour:Odourless

- Specific Gravity:1.00 Ð 1.20

- pH(100 ppm): 5.00 Ð 8.00

- Solubility:100%

APPLICATION, DOSAGE& DILUTION:

- AquaPower's AQUAPRO 20 is dosed to the RO feed water tank or HP pump suction.

- Minimum recommended dosage is of 1ppm and maximum dosage depends on the inlet water quality and parameters. Variation in dosage is subject to inlet water quality and inlet water parameters such as Calcium hardness, Aluminium, Iron content, TDS, Alkalinity, pH and Silica etc.

- AquaPower's AQUAPRO 20 is to be dozed continuously to minimize precipitation of scale and fouling of RO membranes. It is preferred to dose AquaPower's AQUAPRO 20 through closed container by dozing pump to avoid contamination.

- AquaPower's AQUAPRO 20 if needed is to be diluted with RO permeate water.

PACKAGING INFORMATION:

- AquaPower's AQUAPRO 20 is a liquid material and is available in wide variety of customized containers as per user requirement through various delivery methods.

Please contact our company's representative in case of any queries and details.

Cooling Water Treatment Program

The overall objective of a cooling water treatment program is to maintain maximum heat transfer consistent with design. Optimum operating temperature translates into increased unit efficiency and has a significant positive impact upon the cost of power generation.

In the past fifteen years, cooling system operation has changed substantially. Units are being operated for longer periods between turnarounds. Equipment design is more critical at higher temperatures and objectionable impurities are being circulated at higher cycles of concentration. Thus, systems contain a higher potential for scale, corrosion, deposits, and foulants. If improperly diagnosed and treated, the result can be loss of heat transfer, shortened equipment life, unscheduled outages, downtime, and lost production.

The selection process of water treatment chemicals involves consideration of not only the use/cost of products, but also environmental implications, supplier application know-how, inventory management, operator training and safety, and the logistics of feed and control for each system.

Monitoring of the individual systems on a periodic basis by both the plant operating personnel and AQUAPOWER personnel serves the dual purpose of uncovering potential problem areas before they become a problem and for tracking of projected costs vs. actual costs to meet programme objectives of cost performance.

Learn More

Overview

The AQUAPOWER treatment program has been developed based upon:

- Operational data

- Our study of the specifics of the system

- Information provided by on-site personnel

- Plant inspection and evaluation

Plant specific insights gained from the Customer combines with predictive capabilities of AQUAPOWER cooling water treatment program.

We, at AQUAPOWER aim at uncovering potential problem areas before they become a problem and track the projected costs vs. actual costs to meet programme objectives of cost performance.

The AQUAPOWER Water Treatment program offers cost effective, environmentally acceptable products to maintain clean heat transfer surfaces through inorganic/organic deposit control. Our program offers You the optimal usage and performance of water and energy in the plant. Under our treatment program, client is secured of both chemicals & comprehensive training & technical services.

Boiler Water Treatment Program

Processes run at their optimal efficiency and minimal waste give higher returns. We at AQUAPOWER will ensure smooth functioning and minimal exhaustion of resources through our Boiler water treatment programs.

Why AQUAPOWER?

- AQUAPOWER’s AQUASHIELD 02 and AQUASHIELD 09 helps maximize the efficiency to generate Quality Steam.

- Helps in minimizing water usage / wastage.

- Optimizes O&M costs.

- Protects the preheats, boiler, turbines, condensate and process equipment.

- Ensures maintenance of consistent and optimum steaming rate.

- Prevents Scaling and Fouling.